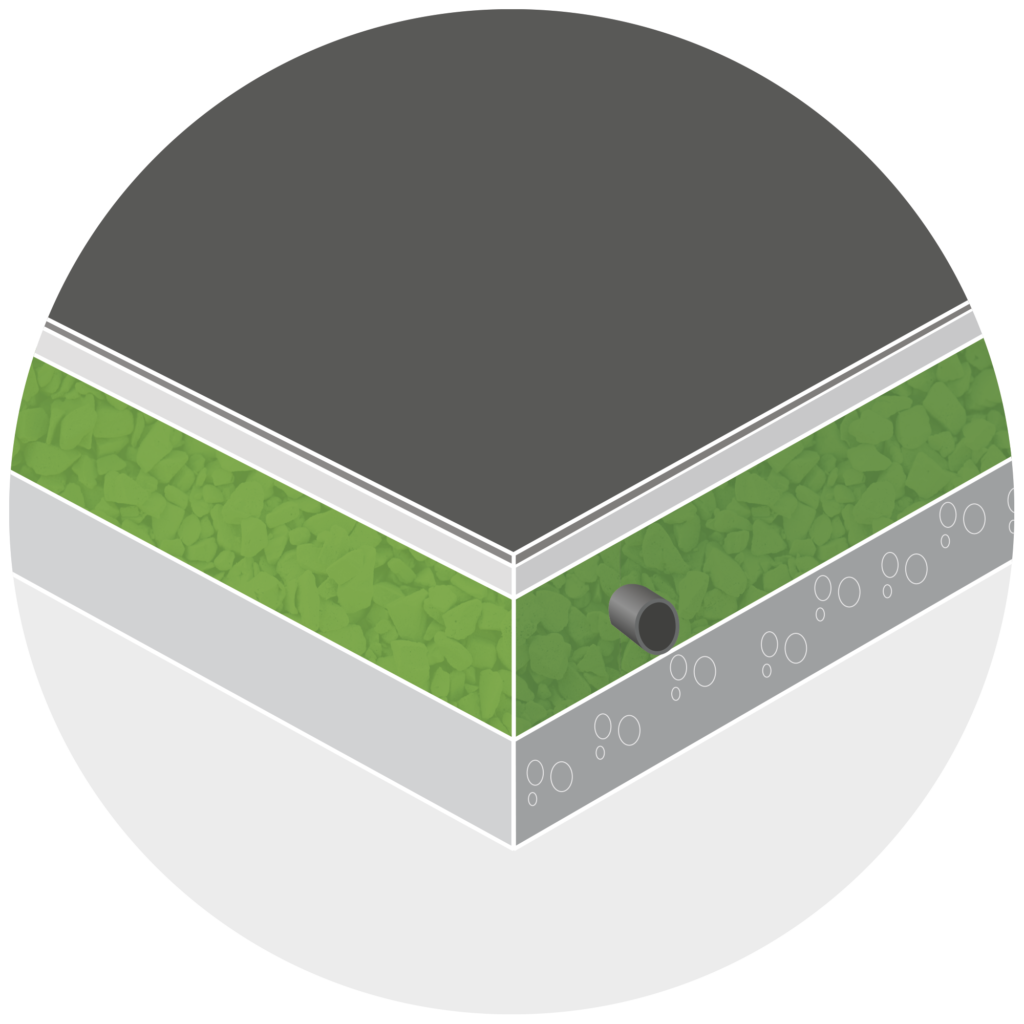

Foamit acts as a ventilated, elevated layer for the tops of population shelters. Foam glass aggregate is well-suited for use as an elevated layer – it’s load bearing and installation is quick. Foamit can be installed without the use of walking blocks, slabs or other supporting structures during installation. High-friction Foamit supports bodyweight even when uncompacted. Its frictional surface is also helpful during installation. Foamit stays in place during a pour rather than spreading around, allowing for an even pouring layer.

By avoiding using support structures during installation, contractors can achieve lower labour and material costs. Less material reduces delivery risk and means fewer supplier visits to the worksite, and a shorter installation time reduces the length of the entire work phase.

Installation on the tops of population shelters is generally carried out by a high-capacity blower or by ordering Foamit sacks from hardware stores. Foamit is classified as fire class A1 and carries an M1-classification. Foamit is produced 100% from recycled materials and contains no organic material or sulphur. Foamit has the lowest carbon footprint in its class, and can be used in Joutsen-labelled buildings.

Contact us

Contact us